Ultranex DTF FIlm Sheets and rolls

DTF Films by Ultranex – the ultimate solution for high-quality Direct-to-Film (DTF) printing. Revolutionizing the textile industry, our premium DTF transfer films ensure seamless compatibility with inkjet printers, delivering vibrant, durable, and efficient fabric transfers. Developed by Vama Prints & Technologies Pvt. Ltd., Ultranex DTF Films guarantee superior performance for all your textile printing needs

Quick Ink drying

No ink leakage even at 6 pass printing without heater on a roll to roll inkjet printer & 90 Nozzle setting on L1800 inkjet printers. Even while printing white on CMYK Black color.

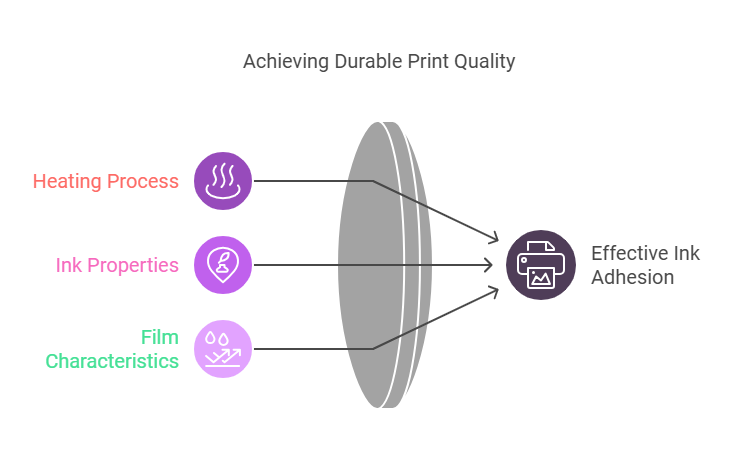

Ultranex DTF Inkjet Film’s inkjet ink receptive coating layer have been developed for optimum ink absorption, as soon as the inkjet ink drop lands on it, Ink will dry rapidly.

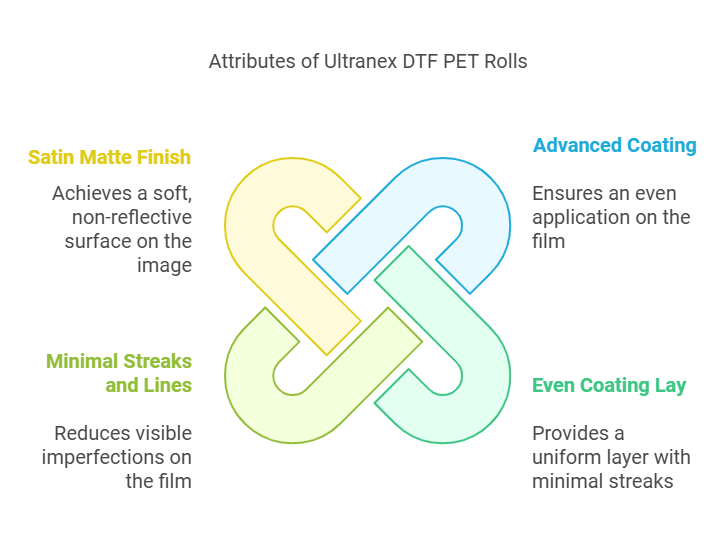

Satin Matte finish to the surface of transferred Image

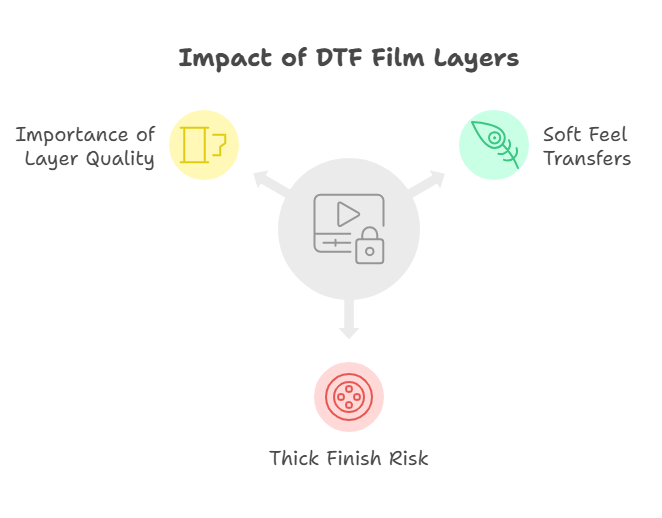

Soft Feel to Transfers

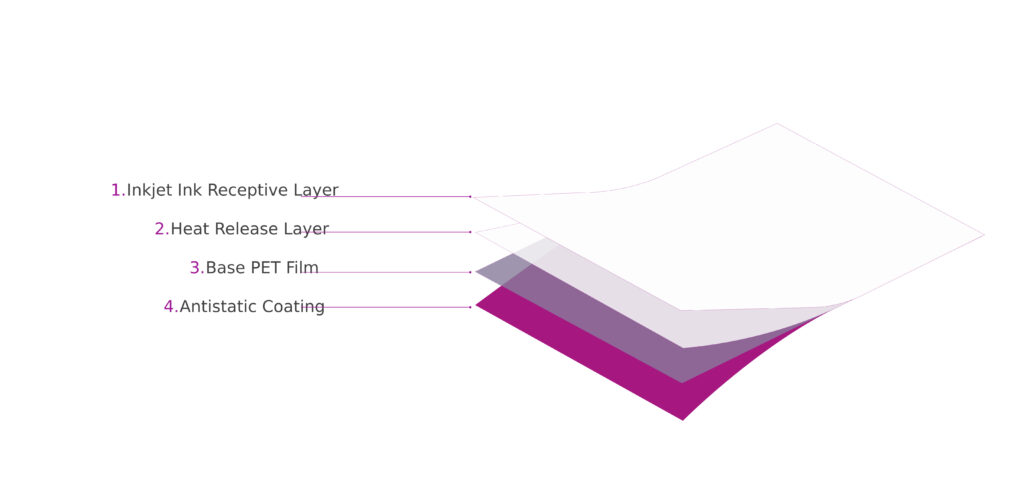

Ultranex DTF Inkjet Films are made with 2 layer technology 1st is the release layer and 2nd is the inkjet in receptive layer. Ink receptive layer after printing and drying becomes part of Ink / label and transfers with the label on the garment.

In Ultranex DTF Film Ink receptive layer is of low hardness to give a soft and smooth feel to transfers.

So even if the inks are soft if the ink receptive layer is not good it will give a thick and hard finish to the transfers.

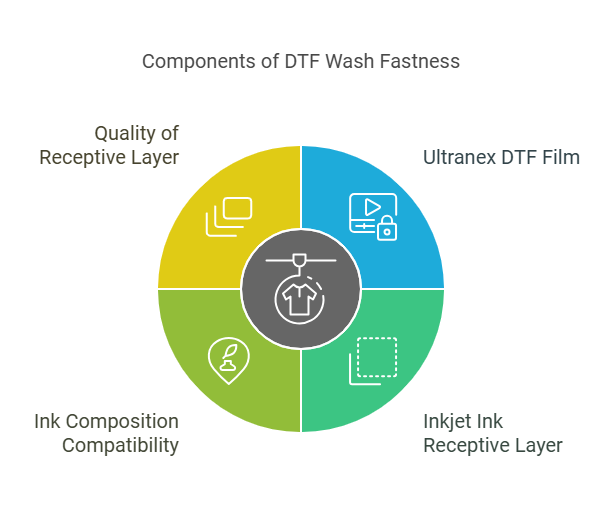

Excellent wash Fastness

Ultranex DTF Heat Release Film adds to the wash fastness of the DTF image on the garment, As the inkjet ink receptive layer will act as scratch resistance layer.

Again ink is always been made responsible to wash fastness & it is but If inkjet ink receptive layer is not friendly with the ink composition or of low quality it will affect wash stability of DTF label on the garment.

Long Shelve life of Film & labels

Printed DTF Labels on the Ultranex DTF film can be transferred even after storage for longer period of time, We have tested it up to 1 year and still transfers good.

| Appearance | Translucent Film |

| Base – PET Film | 75µ |

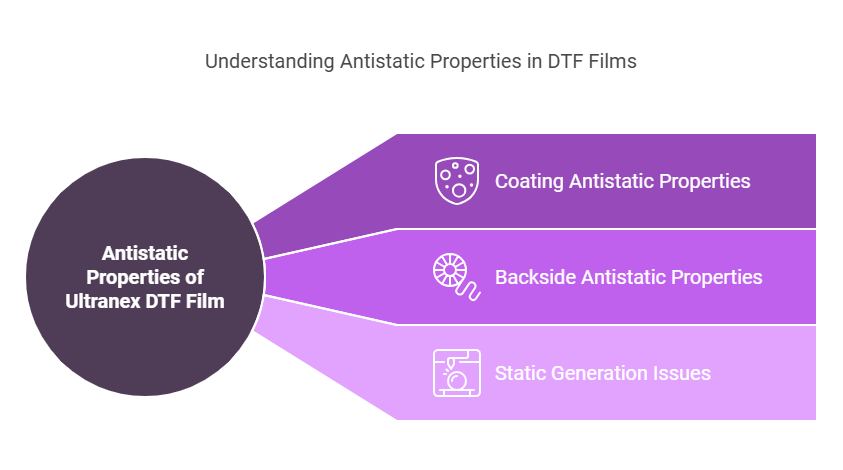

| Side 1 Antistatic Coated | 109 Ω – 1010 Ω |

| Side 2 Matte release coated | Even & Smooth Finish |

| Matte release coating thickness | 11µ (+ / – 2µ) |

| Matte value of release coating | 10 GU (+ / – 1GU) |

| Standard Size | A3, A4, Rolls: 600mmX100Mtrs, 300X100Mtrs |

| Print Hold Out | Medium to High |

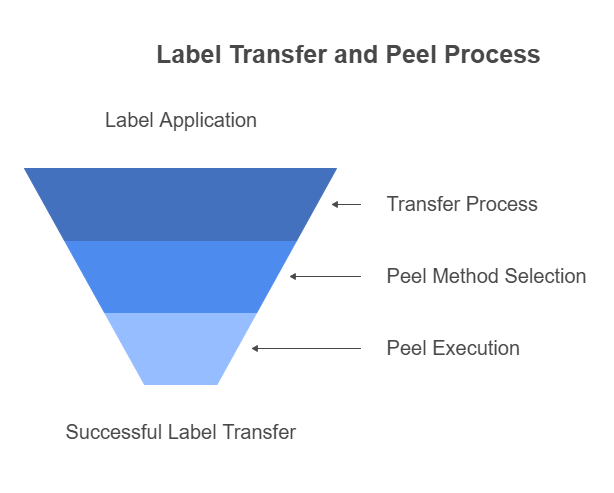

| Release force | Medium to Low (Hot & Cold Peel) |

- It is recommended to wear gloves to avoid damage on the film surface.

- Avoid extra tapping as Ultranex DTF film is inherent antistatic which helps easy Hot Melt powder removal from non printed areas.

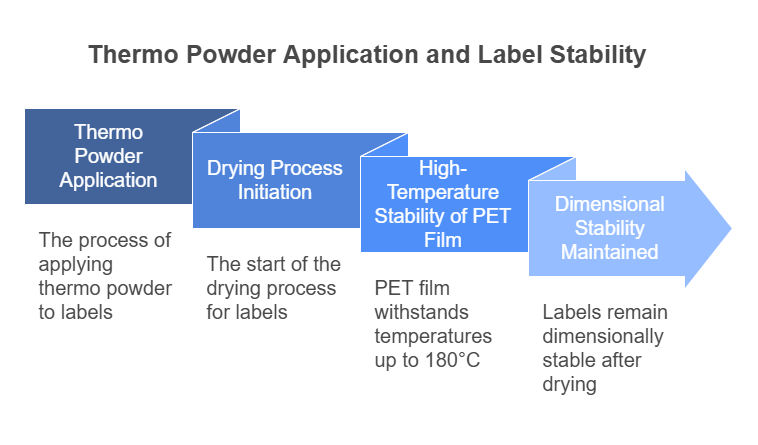

- In drying process we recommend 160°C to 180°C for 3 to 4 Minutes to the printed surface of the film. For best results medium wave IR lamp heater in the shaker is recommended as they are non color sensitive. Note: Oven temp is not the set temperature but the actual temp received on the film.

- Normally; well dried labels will not show sweating or oil on the label surface in storage condition, but it is recommended that ready labels to be kept in moisture proof poly bags to avoid moisture issue.

Transfers can be applied from 160°C to 180°C for 30 to 15 seconds with 2 to 4 bars pressure.

With certain type of design hot peel is not applicable, but we recommend warm to cold peel to get best results.

Note: In case oily stains are found on surface of transferred labels, wipe it with a damp cloth & balance labels should be dried again for 1 to 3 minutes @ 160°C before transfer so any access moisture gets removed.

How to read grade: F = Film, 86= Overall thickness of the film with coating, SM = Silky Matte Finish to Transferred label, 1= Sigle side matte or 2=Both side matte.

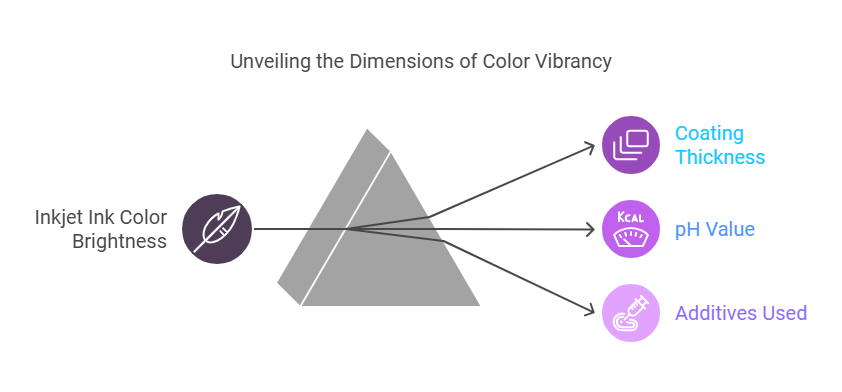

India-made Ultranex DTF Film is a special film designed for printing textile transfers using DTF inkjet printers. This Single side or double-sided film features an antistatic coating for smooth printing and a matte release coating with two layers: a base layer is release Layer and a top layer that readily accepts high quantity of DTF ink. This top layer’s ink receptivity not only enhances printing but also contributes to the wash fastness of the transferred image on your garment. DTF Transfers a printing technology gaining traction across the USA, utilizes inkjet printing for Textile Transfers. The most functional part of DTF Film is the inkjet ink-receptive layer, which quickly sets or dries liquid DTF ink when printing. It opens up the color vibrancy to its fullest. The coating helps in a glitch-free Hot Melt powder application; it is heat stable; in transfer application, it releases smoothly from the base layer & bonds with the ink layer, which serves as a protective layer throughout its life cycle.

Our Happy Clients

Certificate

CERTIFIED ISO 9001:2015

The ISO 9001:2015 certification shows our strong quality management system and signifies that our products have met customers’ expectations. It also demonstrates our ability to consistently deliver products that meet regulatory and company-specific requirements.

CERTIFIED OEKO- TEX STANDARD 100

OEKO-TEX® STANDARD 100 is the standard for textile safety. It indicates that the product has successfully passed safety tests and is free of harmful substances and chemicals. This certification complies with global safety requirements and regulations.

DTF transfer Films and News Related Blogs

Direct-to-Film (DTF) printing has gained considerable popularity in the custom apparel industry due to its versatility and durability. When considering DTF, a common question arises: how long does it actually last? The longevity of DTF transfers is influenced by a confluence of factors, making it a nuanced topic. DTF FILM…

Direct-to-Film (DTF) printing has changed the garment customization industry with its versatility, durability, and ability to print vibrant designs on various fabrics. If you’re considering DTF printing, knowing which printers are compatible is crucial. You should also know what equipment is needed, and whether specific printer models like Epson or…

DTF (Direct to Film) printing has gained immense popularity in a short period. It maximizes your ability to create vibrant designs for various purposes quickly and substrates. Thus, you can make personalized merchandise or even start a profitable print business. However, if you aren’t aware of the right technique of…

Frequently Asked Questions

What is DTF printing?

DTF printing means printing designs onto a special film and transferring them onto fabric using heat. It allows for crisp, full-color prints with precise details. You can use DTF printing for a variety of fabrics like cotton, polyester, twill, denim, canvas, and more.

What are the applications for Ultranex DTF transfer film roll?

Ultranex DTF transfer release film roll is normally used to print heat transfer labels for garments, such as neck, tagless, and litho transfer labels. It has a wide range of grades for different heat transfer applications like screen printing, textile transfers, silicone transfers, and hybrid transfers.

What ink is used for the DTF printing process?

The inks used in DTF printing are sublimation, pigment, and solvent-based. These types of ink have pigments that adhere or stick to the surface of the heat transfer film. This, in turn, gives sharp colors with a long lifespan.

What is the Minimum Order Quantity (MOQ)for buying Ultranex Pet Release Film?

MOQ starts from 5000 sheets for regular buying, but to make trial production, we will supply the required quantity.

Are there any specific care instructions for DTF prints?

Yes. Make sure to gently wash your fabric inside out in cold water. Do not use fabric softeners and bleach on them. Air dry the garment to prevent heat damage. Also, try not to iron directly over the design. You can cover it with a cloth and use low heat.

Do ink transfers hold up the wash?

Yes. DTF transfers can hold up between 60 to 100 washes. The designs show no signs of cracking, fading, or peeling as the transfers are rigorously tested. Moreover, cold water enhances the longevity of the designs.