- +17144000627

- dtf@eximeng.com

- Exim Engineering. 2200 E Winston Road, Anaheim, CA 92806

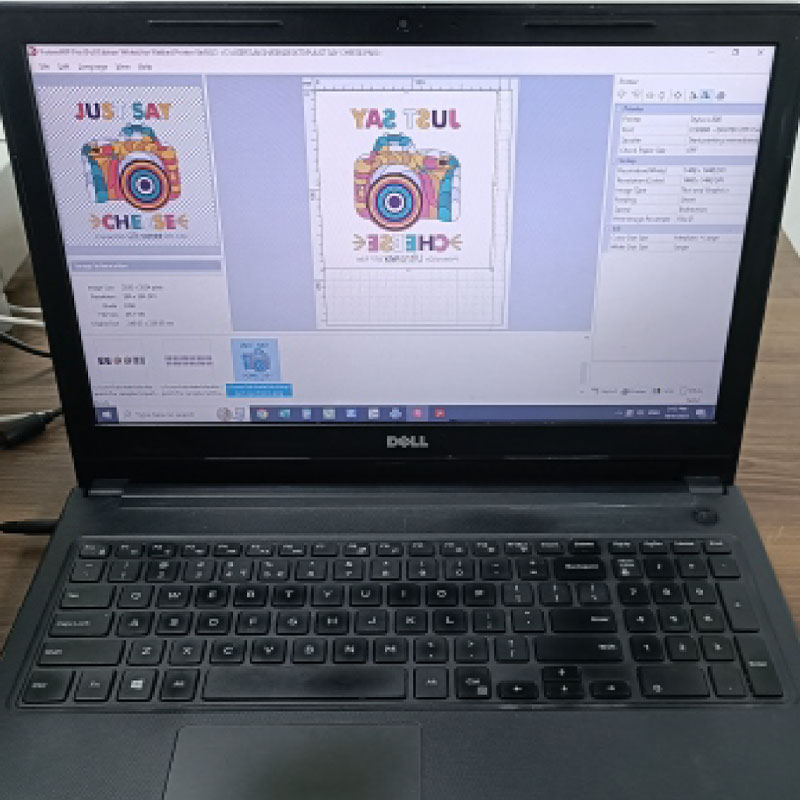

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

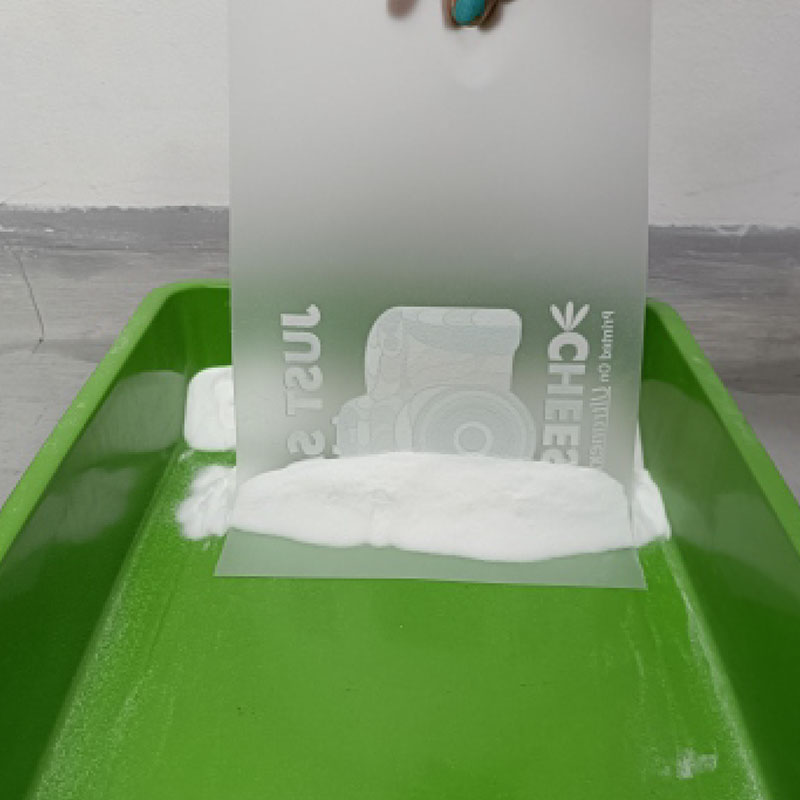

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

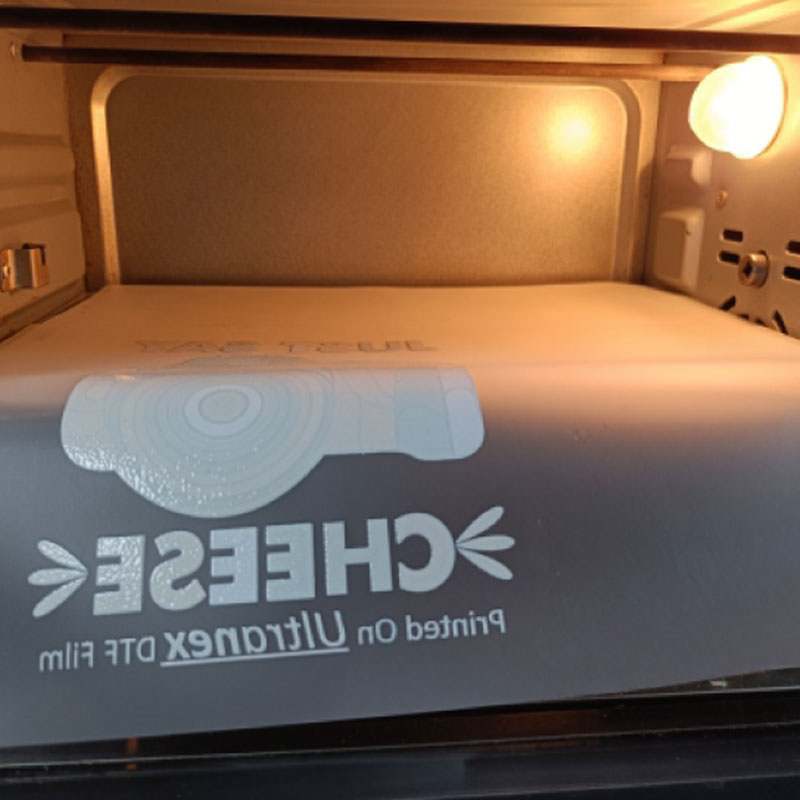

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

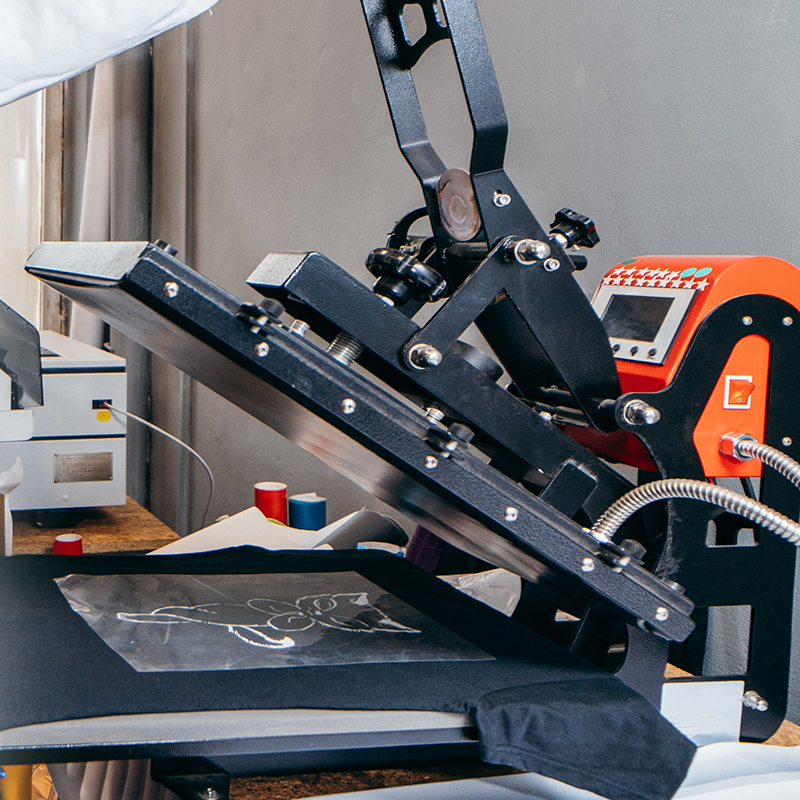

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology

We are pioneers of Innovative DTF Films in India

Eco-friendly water-based coating technology