Direct-to-Film (DTF) printing has gained considerable popularity in the custom apparel industry due to its versatility and durability. When considering DTF, a common question arises: how long does it actually last? The longevity of DTF transfers is influenced by a confluence of factors, making it a nuanced topic.

DTF FILM

Essentially, DTF prints are known for their resilience. Under optimal conditions, a DTF transfer can endure upwards of 50 washes, and in some cases, even surpass the lifespan of the garment itself. This durability stems from the printing process itself, which involves transferring a design onto a specialized film, applying an adhesive powder, and then heat-pressing it onto the fabric. However, several elements can significantly impact this lifespan.

One critical factor is the quality of the materials used. High-grade inks and adhesives are paramount. Premium inks maintain their vibrancy and resist fading, while a strong adhesive ensures the print adheres firmly to the fabric, minimizing the risk of peeling or cracking. Conversely, substandard materials can lead to premature degradation of the print.

The type of fabric also plays a vital role. DTF transfers exhibit excellent adhesion to a wide range of materials, including cotton, polyester, and blends. However, the fabric’s texture, weave, and composition can influence the transfer’s longevity. For instance, smoother fabrics tend to provide a more consistent surface for the adhesive to bond to.

Furthermore, proper care and maintenance are crucial. Washing and drying practices can significantly extend or shorten the lifespan of a DTF print. It is highly recommended to wash garments inside out in cold water, use a gentle wash cycle, and avoid harsh detergents or bleach. Additionally, avoiding direct ironing on the print and minimizing exposure to high heat in dryers can help preserve the print’s integrity.

In practical terms, this means that a well-executed DTF print, applied to a suitable fabric and cared for appropriately, can maintain its quality for an extended period. This makes DTF a reliable option for various applications, from everyday apparel to promotional items and workwear. By understanding the factors that influence DTF transfer longevity and adhering to proper care guidelines, individuals and businesses can maximize the lifespan of their custom prints

READ ALSO – Can a regular printer print DTF transfers?

What is DTF Printing? Everything You Need to Know

In the ever-evolving world of custom apparel and textile decoration, DTF printing—short for Direct to Film printing—has emerged as a revolutionary method that’s transforming the industry. From hobbyists and small business owners to large-scale commercial printers, everyone is exploring this cutting-edge technology for its vibrant colors, versatile applications, and cost-effective production.

If you’re wondering what is DTF printing, this blog by Ultranex DTF will serve as your complete guide. We’ll dive deep into how DTF printing works, its advantages, differences from other printing methods, and why it’s rapidly becoming a preferred choice across the globe.

Understanding What is DTF Printing

DTF printing is a digital printing process that involves printing designs onto a special PET (polyethylene terephthalate) film using water-based pigment inks and then transferring the design onto fabric or other surfaces using a heat press. Unlike traditional methods that require pre-treatment or are limited by fabric type, DTF printing works across a wide range of materials—cotton, polyester, blends, leather, and more.

How Does DTF Printing Work?

To fully understand what is DTF printing, it helps to know the step-by-step process:

- Design Creation – A digital design is created using graphic software such as Adobe Photoshop or CorelDRAW.

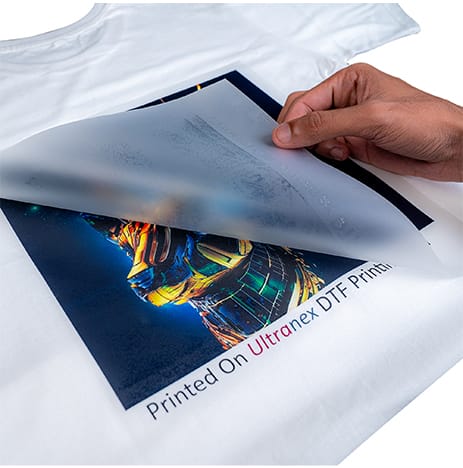

- Printing onto PET Film – The design is printed in reverse order on PET film using a specialized DTF printer and DTF ink.

- Application of Hot Melt Powder – A layer of adhesive powder is applied to the wet ink on the film and then melted using a curing oven or heat press.

- Heat Transfer – The film is placed on the fabric, and a heat press is used to transfer the design permanently.

- Peeling the Film – Once cooled, the PET film is peeled off, leaving a vibrant and durable design on the garment.

This entire process makes DTF printing an efficient, fast, and high-quality option for printing on-demand apparel and custom products.

Why Choose DTF Printing Over Other Methods?

You might still be wondering what is DTF printing good for when compared to screen printing, sublimation, or DTG (Direct to Garment) printing. Here’s a breakdown:

1. Versatility

Unlike sublimation (limited to polyester) or DTG (primarily for cotton), DTF printing works on any fabric type. Whether it’s cotton, silk, nylon, or even denim, DTF offers unmatched versatility.

2. No Pre-Treatment Needed

DTG requires pre-treating garments before printing. In contrast, DTF printing eliminates this step, reducing time and cost.

3. Bright, Durable Prints

DTF provides vivid color reproduction and high wash resistance. The prints don’t crack, peel, or fade easily.

4. Small Runs & Customization

Perfect for small business owners and online stores, DTF printing supports one-off designs and short production runs without hefty setup costs.

5. Cost-Effective

The equipment and consumables for DTF are more affordable compared to DTG or screen printing, especially for startups.

Applications of DTF Printing

Now that you understand what is DTF printing, let’s look at its vast range of applications:

- Custom T-shirts

- Hoodies and Sweatshirts

- Hats and Caps

- Bags and Totes

- Workwear and Uniforms

- Home Décor Items (like pillow covers)

- Promotional Products

DTF is being used in both fashion retail and corporate branding, thanks to its flexibility and high-quality output.

What Makes UltranexDTF.us a Trusted DTF Partner?

At Ultranex DTF, we specialize in providing premium-quality DTF supplies, including printers, PET films, inks, and powders. Whether you’re new to the technology or looking to scale your business, we provide everything needed to master DTF printing.

Here’s why our customers trust us:

- Top-Quality Consumables – Our inks and films produce vivid, sharp, and long-lasting designs.

- Reliable Printers – From desktop models to industrial-grade machines, we have solutions tailored for every user.

- Expert Support – Our DTF experts help troubleshoot, train, and guide you to success.

- Fast Shipping – Located in the USA, we ensure quick delivery and responsive service.

If you’re serious about stepping into the future of garment printing, UltranexDTF.us is your go-to destination.

Common Questions About DTF Printing

Is DTF printing better than DTG?

While both have their place, DTF printing is better for printing on a variety of materials, offers better shelf-life, and requires less maintenance.

Is DTF printing environmentally friendly?

Yes. DTF uses water-based inks and minimizes fabric waste since it doesn’t require pre-treatment chemicals or extra washes.

Can DTF printing be used for bulk orders?

Absolutely. Though ideal for small runs, DTF printing scales well for larger orders without compromising quality.

Does DTF printing crack or fade over time?

Not when done properly. DTF prints, especially with high-quality consumables from UltranexDTF.us, are wash-durable and retain color vibrancy for a long time.

Future of DTF Printing: Trends and Innovations

With increasing demand for personalization and sustainability, DTF printing is paving the way for the future of textile printing. New innovations include:

- Automated powder application and curing machines

- Eco-friendly inks and recyclable PET films

- AI-enhanced color profiling

- Hybrid printing setups that combine DTF and DTG

As a leading supplier, UltranexDTF.us stays ahead of the curve, ensuring our customers access the latest technologies and products.

Final Thoughts: What is DTF Printing and Why It Matters

To sum it up, DTF printing is a game-changer in the world of garment and promotional product customization. With its unparalleled versatility, cost-effectiveness, and professional-grade output, it’s no wonder that so many are making the switch.

Whether you’re starting a side hustle or upgrading your printing setup, understanding what is DTF printing is the first step toward capitalizing on this booming trend. At UltranexDTF.us, we’re committed to being your trusted partner in the DTF journey.

Ready to take the leap? Explore our full line of DTF supplies, printers, and accessories at www.ultranexdtf.us, and let’s bring your designs to life—vivid, bold, and durable!

FAQ’s

Can I cut DTF film after printing?

Yes, you can cut DTF film after printing to separate designs on a gang sheet or to trim excess film. However, be careful not to scratch the printed design.

Is DTF printing better than DTG (Direct-to-Garment) printing?

DTF and DTG are both digital printing methods but have different strengths. DTG prints directly onto fabric and is best for cotton. DTF prints onto film and is more versatile for different fabrics, including polyester and blends, and doesn’t require pre-treatment. The “better” method depends on your specific needs and the types of garments you’re printing on.

What is a “gang sheet” in DTF printing?

A gang sheet is a way to maximize the use of DTF film by arranging multiple designs closely together on a single sheet for printing. This can save on material costs, especially for smaller designs or multiple orders.

Where can I buy DTF film and supplies?

DTF film and related supplies (inks, powders, printers) are available from various online retailers specializing in printing supplies, as well as some local distributors. It’s important to research and choose reputable suppliers for quality products.